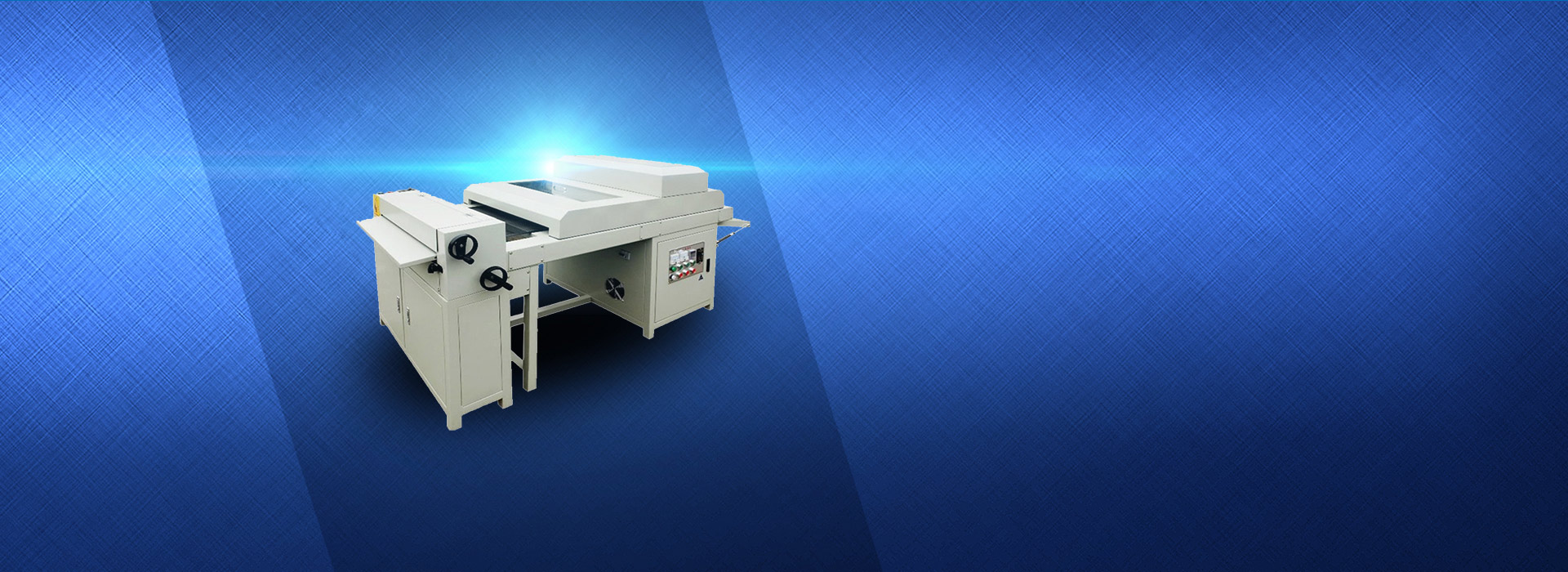

Model | GS-ATC1530S | |

X.Y.Z work area | X axis | 3000mm |

Y axis | 1500mm | |

Z axis | 350mm | |

Model of CNC Automatic tool | ISO-30 | |

Spindle power | 9KW water cooling (with auto tools changer) | |

Spindle rotate speed | 6000~12000rpm | |

CNC Tool-store | 12 tools | |

Vacuum pump | 50m³/h | |

Motor | 1300W Yaskawa servo motor with reducer | |

Transmission | XY axis by helical rack Z by TBI ball screw | |

Table | 5.5kw Vacuum table | |

Controller | Shanghai Weihong | |

Max Processing Thickness | 200mm | |

Cutting speed | 25m/min | |

Max moving speed | 40m/min | |

Max Total Power Rate | 13KW | |

Overall Size:L*W*H | 4.1X2.3X1.9M | |

Weight | 2300KG | |

Suitable Industry:

CNC machining center is a type of 3-dimensional CNC processing equipment designed and manufactured by us to meet nowadays processing pursuit of high precision, high speed, high efficiency under the drastic competition circumstances. The machine has the functions of milling, grinding, polishing and sculpting. It is especially suitable for producing high-grade basin board and other abnormal products made of stone, ceramic, glass and micro-crystal stone. The machine will automatically finish the processing of any required profile by simple setting. The products are of high precision and good glossiness rate. Furthermore, the machine can also run CNC programs to carry out different kinds of sculpting and mould processing etc.

Guarantee & aftersale service

Guarantee for one year, technical support by email or calling except Sunday or other holidays.

User-friendly English manual and Video CD for machine using and maintaining.

中文

中文 English

English